#dot vs python

Explore tagged Tumblr posts

Text

0 notes

Text

Today I was inspired to draw some Yelred so I did. I can’t never tell how much I love this duo and how big brainrot I have over them. It’s 1 am so sorry if the grammar is a bit meh I am sleepy but I should post this

#avm red#ava red#alan becker#animator vs animation#animation vs minecraft#ava yellow#avm yellow#yelred#yellred#ava python#Also first time I reveal their design???#Maybe?#dunno#dont remember#Also did you read the secret text#NOT THE RED DOT#NOOOO

57 notes

·

View notes

Text

Thoughts on Animation vs Coding!

YELLOW MY BOY, I'VE MISSED YOU SO MUCH

So... AvEducation is totally a bunch of dreams, yeah? Yellow literally woke up in this one, I don't care what Alan says. I've connected the dots–

This may be the episode I understand the least, but it was still really fun! I know nothing about Python, so I was absolutely lost lol

I love the laptop, and I love how Yellow was able to bring it back in the end. "hello yellow" is extremely cute.

I do think this post sums up the cons pretty well; Yellow didn't go through the learning process like Orange did in previous episodes. he seemed to already know how to code pretty well, and then pulled out the ability to code an AI (right? that's what that was?) right at the end. That does bother me a bit.

But the episode was fun, and I'm happy to see the team branching out with other characters! (and we haven't seen the CG in a proper episode in a while)

#animator vs animation#alan becker#animation vs education#animation vs coding#rage's ramblings about sticks#Yellow's little pat on the laptop at the beginning was so cute

31 notes

·

View notes

Text

Vessel Tank Cleaning

Vessel Tank Cleaning

Ultimate Expert Guide to Crude Oil Storage Tank Cleaning: Advanced Techniques & Operational Mastery

I. Hyper-Detailed Sludge Analysis

1.1 Molecular-Level Characterization

FTIR Spectroscopy Fingerprinting:

Key peaks:

2,920 cm⁻¹ (aliphatic C-H)

1,700 cm⁻¹ (carbonyl groups from oxidation)

Thermogravimetric Analysis (TGA):

Fig 1.1: Weight loss curve showing:

20% volatiles (<150°C)

45% pyrolyzables (150-500°C)

35% inorganic residue (>500°C)

1.2 Rheological Modeling

Herschel-Bulkley Parameters:

math

\tau = \tau_y + K \dot{\gamma}^n

Typical sludge values:

τ_y (yield stress): 180-220 Pa

K (consistency index): 45-60 Pa·sⁿ

n (flow index): 0.3-0.5

II. Next-Gen Cleaning Systems

Thermal shock (-196°C pulsed application)

Mechanical disaggregation

Effectiveness:

92% sludge removal in carbon steel tanks

40% reduction in hazardous waste vs chemical methods

III. Operational Engineering

3.1 Computational Fluid Dynamics (CFD)

Ventilation Simulation:

Fig 3.1: Velocity contours showing dead zones

Optimal fan placement:

45° angle from tank floor

2 m/s minimum face velocity

3.2 Mechanical Stress Analysis

FEA of Sludge Removal Forces:

Critical stress points during robotic cleaning:

Tank floor: 85 MPa (vs yield strength of 245 MPa)

Wall junctions: 120 MPa (require monitoring)

IV. HSE Quantum Leap

4.1 Predictive Gas Monitoring

Machine Learning Algorithm:

python

def predict_h2s_risk(temperature, pressure, crude_type):

model = load('h2s_predictor.h5')

return model.predict([[temp, press, crude]])

Accuracy: 94% (validated with field data)

4.2 Exoskeleton PPE

Specifications:

Powered assist: 20 kg lift capacity

Integrated gas sensors

8-hour battery life

V. Economic Optimization

5.1 Monte Carlo Cost Simulation

Input Variables:

Sludge density (normal distribution: μ=1.2 g/cm³, σ=0.1)

Labor productivity (triangular distribution: min=4m³/day, max=8m³/day)

Output:

90% confidence interval: $2.4M - $3.1M per major cleaning

5.2 Hydrocarbon Recovery ROI

Formula:

Math

Vessel Tank Cleaning

ROI = \frac{(V_{rec} \times P_{crude}) - C_{cleaning}}{C_{cleaning}} \times 100

Case: 80% recovery from 10,000m³ sludge = $1.2M value at $60/bbl

VI. Digital Twin Implementation

6.1 Live Sensor Network

IoT Deployment Map:

Vibration sensors (SKF @ 5 points)

Corrosion coupons with RFID

Ultrasonic thickness gauges

6.2 Blockchain Documentation

Smart Contract Logic:

solidity

function approveWasteDisposal() public {

require(qualityCheck == true);

require(regulatorApproval == true);

wasteApproved = true;

}

VII. Extreme Case Studies

7.1 Arctic Conditions Cleaning

Challenge: -40°C operational limit

Solution:

Insulated cleaning tent with air heaters

Methanol-based antifreeze additives

Result: 78% efficiency (vs 92% in temperate climates)

7.2 Floating Roof Tank Rescue

Incident: 200,000bbl tank roof collapse

Action Plan:

Emergency nitrogen blanketing

Step-wise robotic debris removal

3D laser scanning for structural assessment

VIII. Future Tech Roadmap

8.1 2025-2027 Horizon

Self-Propelled Nanobots:

Size: 50-100nm

Propulsion: Magnetic field guidance

Capacity: 1kg sludge/hr per million units

8.2 Plasma Gasification

Prototype Results:

99.99% hydrocarbon destruction

Syngas byproduct (15 MJ/kg energy content)

IX. Master Checklist Suite

9.1 Pre-Job Safety Analysis

Confined space permit validation

Rescue team on standby (max 5 min response)

Redundant gas detection system check

9.2 Waste Tracking Manifest

Digital Form Fields:

GPS coordinates of generation

Chain of custody signatures (biometric)

Real-time disposal facility verification

X. Global Benchmarking

10.1 Regional Productivity Metrics

Region Avg Cleaning Days/10,000m³ Cost/m³ (USD)

Middle East 18 120

North America 22 150

Southeast Asia 25 95

10.2 Regulatory Scorecard

Strictest Compliance:

Norway (PSA norms)

Canada (AER Directive 071)

Singapore (MOM Confined Space Regs)

Final Recommendation Package:

Immediate Action: Deploy robotic cleaners with real-time viscosity monitoring

Mid-Term Investment: Install permanent tank IoT sensor arrays

Long-Term Strategy: Partner with nanotech developers for next-gen solutions

Appendices:

A. API 653 Amendment Tracker (2024 Ed.)

B. H2S Exposure Response Flowcharts

C. Sludge Density Conversion Calculator

0 notes

Text

Vessel Tank Cleaning

Vessel Tank Cleaning

Ultimate Expert Guide to Crude Oil Storage Tank Cleaning: Advanced Techniques & Operational Mastery

I. Hyper-Detailed Sludge Analysis

1.1 Molecular-Level Characterization

FTIR Spectroscopy Fingerprinting:

Key peaks:

2,920 cm⁻¹ (aliphatic C-H)

1,700 cm⁻¹ (carbonyl groups from oxidation)

Thermogravimetric Analysis (TGA):

Fig 1.1: Weight loss curve showing:

20% volatiles (<150°C)

45% pyrolyzables (150-500°C)

35% inorganic residue (>500°C)

1.2 Rheological Modeling

Herschel-Bulkley Parameters:

math

\tau = \tau_y + K \dot{\gamma}^n

Typical sludge values:

τ_y (yield stress): 180-220 Pa

K (consistency index): 45-60 Pa·sⁿ

n (flow index): 0.3-0.5

II. Next-Gen Cleaning Systems

Thermal shock (-196°C pulsed application)

Mechanical disaggregation

Effectiveness:

92% sludge removal in carbon steel tanks

40% reduction in hazardous waste vs chemical methods

III. Operational Engineering

3.1 Computational Fluid Dynamics (CFD)

Ventilation Simulation:

Fig 3.1: Velocity contours showing dead zones

Optimal fan placement:

45° angle from tank floor

2 m/s minimum face velocity

3.2 Mechanical Stress Analysis

FEA of Sludge Removal Forces:

Critical stress points during robotic cleaning:

Tank floor: 85 MPa (vs yield strength of 245 MPa)

Wall junctions: 120 MPa (require monitoring)

IV. HSE Quantum Leap

4.1 Predictive Gas Monitoring

Machine Learning Algorithm:

python

def predict_h2s_risk(temperature, pressure, crude_type):

model = load('h2s_predictor.h5')

return model.predict([[temp, press, crude]])

Accuracy: 94% (validated with field data)

4.2 Exoskeleton PPE

Specifications:

Powered assist: 20 kg lift capacity

Integrated gas sensors

8-hour battery life

V. Economic Optimization

5.1 Monte Carlo Cost Simulation

Input Variables:

Sludge density (normal distribution: μ=1.2 g/cm³, σ=0.1)

Labor productivity (triangular distribution: min=4m³/day, max=8m³/day)

Output:

90% confidence interval: $2.4M - $3.1M per major cleaning

5.2 Hydrocarbon Recovery ROI

Formula:

Math

Vessel Tank Cleaning

ROI = \frac{(V_{rec} \times P_{crude}) - C_{cleaning}}{C_{cleaning}} \times 100

Case: 80% recovery from 10,000m³ sludge = $1.2M value at $60/bbl

VI. Digital Twin Implementation

6.1 Live Sensor Network

IoT Deployment Map:

Vibration sensors (SKF @ 5 points)

Corrosion coupons with RFID

Ultrasonic thickness gauges

6.2 Blockchain Documentation

Smart Contract Logic:

solidity

function approveWasteDisposal() public {

require(qualityCheck == true);

require(regulatorApproval == true);

wasteApproved = true;

}

VII. Extreme Case Studies

7.1 Arctic Conditions Cleaning

Challenge: -40°C operational limit

Solution:

Insulated cleaning tent with air heaters

Methanol-based antifreeze additives

Result: 78% efficiency (vs 92% in temperate climates)

7.2 Floating Roof Tank Rescue

Incident: 200,000bbl tank roof collapse

Action Plan:

Emergency nitrogen blanketing

Step-wise robotic debris removal

3D laser scanning for structural assessment

VIII. Future Tech Roadmap

8.1 2025-2027 Horizon

Self-Propelled Nanobots:

Size: 50-100nm

Propulsion: Magnetic field guidance

Capacity: 1kg sludge/hr per million units

8.2 Plasma Gasification

Prototype Results:

99.99% hydrocarbon destruction

Syngas byproduct (15 MJ/kg energy content)

IX. Master Checklist Suite

9.1 Pre-Job Safety Analysis

Confined space permit validation

Rescue team on standby (max 5 min response)

Redundant gas detection system check

9.2 Waste Tracking Manifest

Digital Form Fields:

GPS coordinates of generation

Chain of custody signatures (biometric)

Real-time disposal facility verification

X. Global Benchmarking

10.1 Regional Productivity Metrics

Region Avg Cleaning Days/10,000m³ Cost/m³ (USD)

Middle East 18 120

North America 22 150

Southeast Asia 25 95

10.2 Regulatory Scorecard

Strictest Compliance:

Norway (PSA norms)

Canada (AER Directive 071)

Singapore (MOM Confined Space Regs)

Final Recommendation Package:

Immediate Action: Deploy robotic cleaners with real-time viscosity monitoring

Mid-Term Investment: Install permanent tank IoT sensor arrays

Long-Term Strategy: Partner with nanotech developers for next-gen solutions

Appendices:

A. API 653 Amendment Tracker (2024 Ed.)

B. H2S Exposure Response Flowcharts

C. Sludge Density Conversion Calculator

0 notes

Text

Vessel Tank Cleaning

Vessel Tank Cleaning

Ultimate Expert Guide to Crude Oil Storage Tank Cleaning: Advanced Techniques & Operational Mastery

I. Hyper-Detailed Sludge Analysis

1.1 Molecular-Level Characterization

FTIR Spectroscopy Fingerprinting:

Key peaks:

2,920 cm⁻¹ (aliphatic C-H)

1,700 cm⁻¹ (carbonyl groups from oxidation)

Thermogravimetric Analysis (TGA):

Fig 1.1: Weight loss curve showing:

20% volatiles (<150°C)

45% pyrolyzables (150-500°C)

35% inorganic residue (>500°C)

1.2 Rheological Modeling

Herschel-Bulkley Parameters:

math

\tau = \tau_y + K \dot{\gamma}^n

Typical sludge values:

τ_y (yield stress): 180-220 Pa

K (consistency index): 45-60 Pa·sⁿ

n (flow index): 0.3-0.5

II. Next-Gen Cleaning Systems

Thermal shock (-196°C pulsed application)

Mechanical disaggregation

Effectiveness:

92% sludge removal in carbon steel tanks

40% reduction in hazardous waste vs chemical methods

III. Operational Engineering

3.1 Computational Fluid Dynamics (CFD)

Ventilation Simulation:

Fig 3.1: Velocity contours showing dead zones

Optimal fan placement:

45° angle from tank floor

2 m/s minimum face velocity

3.2 Mechanical Stress Analysis

FEA of Sludge Removal Forces:

Critical stress points during robotic cleaning:

Tank floor: 85 MPa (vs yield strength of 245 MPa)

Wall junctions: 120 MPa (require monitoring)

IV. HSE Quantum Leap

4.1 Predictive Gas Monitoring

Machine Learning Algorithm:

python

def predict_h2s_risk(temperature, pressure, crude_type):

model = load('h2s_predictor.h5')

return model.predict([[temp, press, crude]])

Accuracy: 94% (validated with field data)

4.2 Exoskeleton PPE

Specifications:

Powered assist: 20 kg lift capacity

Integrated gas sensors

8-hour battery life

V. Economic Optimization

5.1 Monte Carlo Cost Simulation

Input Variables:

Sludge density (normal distribution: μ=1.2 g/cm³, σ=0.1)

Labor productivity (triangular distribution: min=4m³/day, max=8m³/day)

Output:

90% confidence interval: $2.4M - $3.1M per major cleaning

5.2 Hydrocarbon Recovery ROI

Formula:

Math

Vessel Tank Cleaning

ROI = \frac{(V_{rec} \times P_{crude}) - C_{cleaning}}{C_{cleaning}} \times 100

Case: 80% recovery from 10,000m³ sludge = $1.2M value at $60/bbl

VI. Digital Twin Implementation

6.1 Live Sensor Network

IoT Deployment Map:

Vibration sensors (SKF @ 5 points)

Corrosion coupons with RFID

Ultrasonic thickness gauges

6.2 Blockchain Documentation

Smart Contract Logic:

solidity

function approveWasteDisposal() public {

require(qualityCheck == true);

require(regulatorApproval == true);

wasteApproved = true;

}

VII. Extreme Case Studies

7.1 Arctic Conditions Cleaning

Challenge: -40°C operational limit

Solution:

Insulated cleaning tent with air heaters

Methanol-based antifreeze additives

Result: 78% efficiency (vs 92% in temperate climates)

7.2 Floating Roof Tank Rescue

Incident: 200,000bbl tank roof collapse

Action Plan:

Emergency nitrogen blanketing

Step-wise robotic debris removal

3D laser scanning for structural assessment

VIII. Future Tech Roadmap

8.1 2025-2027 Horizon

Self-Propelled Nanobots:

Size: 50-100nm

Propulsion: Magnetic field guidance

Capacity: 1kg sludge/hr per million units

8.2 Plasma Gasification

Prototype Results:

99.99% hydrocarbon destruction

Syngas byproduct (15 MJ/kg energy content)

IX. Master Checklist Suite

9.1 Pre-Job Safety Analysis

Confined space permit validation

Rescue team on standby (max 5 min response)

Redundant gas detection system check

9.2 Waste Tracking Manifest

Digital Form Fields:

GPS coordinates of generation

Chain of custody signatures (biometric)

Real-time disposal facility verification

X. Global Benchmarking

10.1 Regional Productivity Metrics

Region Avg Cleaning Days/10,000m³ Cost/m³ (USD)

Middle East 18 120

North America 22 150

Southeast Asia 25 95

10.2 Regulatory Scorecard

Strictest Compliance:

Norway (PSA norms)

Canada (AER Directive 071)

Singapore (MOM Confined Space Regs)

Final Recommendation Package:

Immediate Action: Deploy robotic cleaners with real-time viscosity monitoring

Mid-Term Investment: Install permanent tank IoT sensor arrays

Long-Term Strategy: Partner with nanotech developers for next-gen solutions

Appendices:

A. API 653 Amendment Tracker (2024 Ed.)

B. H2S Exposure Response Flowcharts

C. Sludge Density Conversion Calculator

0 notes

Text

Vessel Tank Cleaning

Vessel Tank Cleaning

Ultimate Expert Guide to Crude Oil Storage Tank Cleaning: Advanced Techniques & Operational Mastery

I. Hyper-Detailed Sludge Analysis

1.1 Molecular-Level Characterization

FTIR Spectroscopy Fingerprinting:

Key peaks:

2,920 cm⁻¹ (aliphatic C-H)

1,700 cm⁻¹ (carbonyl groups from oxidation)

Thermogravimetric Analysis (TGA):

Fig 1.1: Weight loss curve showing:

20% volatiles (<150°C)

45% pyrolyzables (150-500°C)

35% inorganic residue (>500°C)

1.2 Rheological Modeling

Herschel-Bulkley Parameters:

math

\tau = \tau_y + K \dot{\gamma}^n

Typical sludge values:

τ_y (yield stress): 180-220 Pa

K (consistency index): 45-60 Pa·sⁿ

n (flow index): 0.3-0.5

II. Next-Gen Cleaning Systems

Thermal shock (-196°C pulsed application)

Mechanical disaggregation

Effectiveness:

92% sludge removal in carbon steel tanks

40% reduction in hazardous waste vs chemical methods

III. Operational Engineering

3.1 Computational Fluid Dynamics (CFD)

Ventilation Simulation:

Fig 3.1: Velocity contours showing dead zones

Optimal fan placement:

45° angle from tank floor

2 m/s minimum face velocity

3.2 Mechanical Stress Analysis

FEA of Sludge Removal Forces:

Critical stress points during robotic cleaning:

Tank floor: 85 MPa (vs yield strength of 245 MPa)

Wall junctions: 120 MPa (require monitoring)

IV. HSE Quantum Leap

4.1 Predictive Gas Monitoring

Machine Learning Algorithm:

python

def predict_h2s_risk(temperature, pressure, crude_type):

model = load('h2s_predictor.h5')

return model.predict([[temp, press, crude]])

Accuracy: 94% (validated with field data)

4.2 Exoskeleton PPE

Specifications:

Powered assist: 20 kg lift capacity

Integrated gas sensors

8-hour battery life

V. Economic Optimization

5.1 Monte Carlo Cost Simulation

Input Variables:

Sludge density (normal distribution: μ=1.2 g/cm³, σ=0.1)

Labor productivity (triangular distribution: min=4m³/day, max=8m³/day)

Output:

90% confidence interval: $2.4M - $3.1M per major cleaning

5.2 Hydrocarbon Recovery ROI

Formula:

Math

Vessel Tank Cleaning

ROI = \frac{(V_{rec} \times P_{crude}) - C_{cleaning}}{C_{cleaning}} \times 100

Case: 80% recovery from 10,000m³ sludge = $1.2M value at $60/bbl

VI. Digital Twin Implementation

6.1 Live Sensor Network

IoT Deployment Map:

Vibration sensors (SKF @ 5 points)

Corrosion coupons with RFID

Ultrasonic thickness gauges

6.2 Blockchain Documentation

Smart Contract Logic:

solidity

function approveWasteDisposal() public {

require(qualityCheck == true);

require(regulatorApproval == true);

wasteApproved = true;

}

VII. Extreme Case Studies

7.1 Arctic Conditions Cleaning

Challenge: -40°C operational limit

Solution:

Insulated cleaning tent with air heaters

Methanol-based antifreeze additives

Result: 78% efficiency (vs 92% in temperate climates)

7.2 Floating Roof Tank Rescue

Incident: 200,000bbl tank roof collapse

Action Plan:

Emergency nitrogen blanketing

Step-wise robotic debris removal

3D laser scanning for structural assessment

VIII. Future Tech Roadmap

8.1 2025-2027 Horizon

Self-Propelled Nanobots:

Size: 50-100nm

Propulsion: Magnetic field guidance

Capacity: 1kg sludge/hr per million units

8.2 Plasma Gasification

Prototype Results:

99.99% hydrocarbon destruction

Syngas byproduct (15 MJ/kg energy content)

IX. Master Checklist Suite

9.1 Pre-Job Safety Analysis

Confined space permit validation

Rescue team on standby (max 5 min response)

Redundant gas detection system check

9.2 Waste Tracking Manifest

Digital Form Fields:

GPS coordinates of generation

Chain of custody signatures (biometric)

Real-time disposal facility verification

X. Global Benchmarking

10.1 Regional Productivity Metrics

Region Avg Cleaning Days/10,000m³ Cost/m³ (USD)

Middle East 18 120

North America 22 150

Southeast Asia 25 95

10.2 Regulatory Scorecard

Strictest Compliance:

Norway (PSA norms)

Canada (AER Directive 071)

Singapore (MOM Confined Space Regs)

Final Recommendation Package:

Immediate Action: Deploy robotic cleaners with real-time viscosity monitoring

Mid-Term Investment: Install permanent tank IoT sensor arrays

Long-Term Strategy: Partner with nanotech developers for next-gen solutions

Appendices:

A. API 653 Amendment Tracker (2024 Ed.)

B. H2S Exposure Response Flowcharts

C. Sludge Density Conversion Calculator

0 notes

Text

Vessel Tank Cleaning

Vessel Tank Cleaning

Ultimate Expert Guide to Crude Oil Storage Tank Cleaning: Advanced Techniques & Operational Mastery

I. Hyper-Detailed Sludge Analysis

1.1 Molecular-Level Characterization

FTIR Spectroscopy Fingerprinting:

Key peaks:

2,920 cm⁻¹ (aliphatic C-H)

1,700 cm⁻¹ (carbonyl groups from oxidation)

Thermogravimetric Analysis (TGA):

Fig 1.1: Weight loss curve showing:

20% volatiles (<150°C)

45% pyrolyzables (150-500°C)

35% inorganic residue (>500°C)

1.2 Rheological Modeling

Herschel-Bulkley Parameters:

math

\tau = \tau_y + K \dot{\gamma}^n

Typical sludge values:

τ_y (yield stress): 180-220 Pa

K (consistency index): 45-60 Pa·sⁿ

n (flow index): 0.3-0.5

II. Next-Gen Cleaning Systems

Thermal shock (-196°C pulsed application)

Mechanical disaggregation

Effectiveness:

92% sludge removal in carbon steel tanks

40% reduction in hazardous waste vs chemical methods

III. Operational Engineering

3.1 Computational Fluid Dynamics (CFD)

Ventilation Simulation:

Fig 3.1: Velocity contours showing dead zones

Optimal fan placement:

45° angle from tank floor

2 m/s minimum face velocity

3.2 Mechanical Stress Analysis

FEA of Sludge Removal Forces:

Critical stress points during robotic cleaning:

Tank floor: 85 MPa (vs yield strength of 245 MPa)

Wall junctions: 120 MPa (require monitoring)

IV. HSE Quantum Leap

4.1 Predictive Gas Monitoring

Machine Learning Algorithm:

python

def predict_h2s_risk(temperature, pressure, crude_type):

model = load('h2s_predictor.h5')

return model.predict([[temp, press, crude]])

Accuracy: 94% (validated with field data)

4.2 Exoskeleton PPE

Specifications:

Powered assist: 20 kg lift capacity

Integrated gas sensors

8-hour battery life

V. Economic Optimization

5.1 Monte Carlo Cost Simulation

Input Variables:

Sludge density (normal distribution: μ=1.2 g/cm³, σ=0.1)

Labor productivity (triangular distribution: min=4m³/day, max=8m³/day)

Output:

90% confidence interval: $2.4M - $3.1M per major cleaning

5.2 Hydrocarbon Recovery ROI

Formula:

Math

Vessel Tank Cleaning

ROI = \frac{(V_{rec} \times P_{crude}) - C_{cleaning}}{C_{cleaning}} \times 100

Case: 80% recovery from 10,000m³ sludge = $1.2M value at $60/bbl

VI. Digital Twin Implementation

6.1 Live Sensor Network

IoT Deployment Map:

Vibration sensors (SKF @ 5 points)

Corrosion coupons with RFID

Ultrasonic thickness gauges

6.2 Blockchain Documentation

Smart Contract Logic:

solidity

function approveWasteDisposal() public {

require(qualityCheck == true);

require(regulatorApproval == true);

wasteApproved = true;

}

VII. Extreme Case Studies

7.1 Arctic Conditions Cleaning

Challenge: -40°C operational limit

Solution:

Insulated cleaning tent with air heaters

Methanol-based antifreeze additives

Result: 78% efficiency (vs 92% in temperate climates)

7.2 Floating Roof Tank Rescue

Incident: 200,000bbl tank roof collapse

Action Plan:

Emergency nitrogen blanketing

Step-wise robotic debris removal

3D laser scanning for structural assessment

VIII. Future Tech Roadmap

8.1 2025-2027 Horizon

Self-Propelled Nanobots:

Size: 50-100nm

Propulsion: Magnetic field guidance

Capacity: 1kg sludge/hr per million units

8.2 Plasma Gasification

Prototype Results:

99.99% hydrocarbon destruction

Syngas byproduct (15 MJ/kg energy content)

IX. Master Checklist Suite

9.1 Pre-Job Safety Analysis

Confined space permit validation

Rescue team on standby (max 5 min response)

Redundant gas detection system check

9.2 Waste Tracking Manifest

Digital Form Fields:

GPS coordinates of generation

Chain of custody signatures (biometric)

Real-time disposal facility verification

X. Global Benchmarking

10.1 Regional Productivity Metrics

Region Avg Cleaning Days/10,000m³ �� Cost/m³ (USD)

Middle East 18 120

North America 22 150

Southeast Asia 25 95

10.2 Regulatory Scorecard

Strictest Compliance:

Norway (PSA norms)

Canada (AER Directive 071)

Singapore (MOM Confined Space Regs)

Final Recommendation Package:

Immediate Action: Deploy robotic cleaners with real-time viscosity monitoring

Mid-Term Investment: Install permanent tank IoT sensor arrays

Long-Term Strategy: Partner with nanotech developers for next-gen solutions

Appendices:

A. API 653 Amendment Tracker (2024 Ed.)

B. H2S Exposure Response Flowcharts

C. Sludge Density Conversion Calculator

0 notes

Text

Vessel Tank Cleaning

Vessel Tank Cleaning

Ultimate Expert Guide to Crude Oil Storage Tank Cleaning: Advanced Techniques & Operational Mastery

I. Hyper-Detailed Sludge Analysis

1.1 Molecular-Level Characterization

FTIR Spectroscopy Fingerprinting:

Key peaks:

2,920 cm⁻¹ (aliphatic C-H)

1,700 cm⁻¹ (carbonyl groups from oxidation)

Thermogravimetric Analysis (TGA):

Fig 1.1: Weight loss curve showing:

20% volatiles (<150°C)

45% pyrolyzables (150-500°C)

35% inorganic residue (>500°C)

1.2 Rheological Modeling

Herschel-Bulkley Parameters:

math

\tau = \tau_y + K \dot{\gamma}^n

Typical sludge values:

τ_y (yield stress): 180-220 Pa

K (consistency index): 45-60 Pa·sⁿ

n (flow index): 0.3-0.5

II. Next-Gen Cleaning Systems

Thermal shock (-196°C pulsed application)

Mechanical disaggregation

Effectiveness:

92% sludge removal in carbon steel tanks

40% reduction in hazardous waste vs chemical methods

III. Operational Engineering

3.1 Computational Fluid Dynamics (CFD)

Ventilation Simulation:

Fig 3.1: Velocity contours showing dead zones

Optimal fan placement:

45° angle from tank floor

2 m/s minimum face velocity

3.2 Mechanical Stress Analysis

FEA of Sludge Removal Forces:

Critical stress points during robotic cleaning:

Tank floor: 85 MPa (vs yield strength of 245 MPa)

Wall junctions: 120 MPa (require monitoring)

IV. HSE Quantum Leap

4.1 Predictive Gas Monitoring

Machine Learning Algorithm:

python

def predict_h2s_risk(temperature, pressure, crude_type):

model = load('h2s_predictor.h5')

return model.predict([[temp, press, crude]])

Accuracy: 94% (validated with field data)

4.2 Exoskeleton PPE

Specifications:

Powered assist: 20 kg lift capacity

Integrated gas sensors

8-hour battery life

V. Economic Optimization

5.1 Monte Carlo Cost Simulation

Input Variables:

Sludge density (normal distribution: μ=1.2 g/cm³, σ=0.1)

Labor productivity (triangular distribution: min=4m³/day, max=8m³/day)

Output:

90% confidence interval: $2.4M - $3.1M per major cleaning

5.2 Hydrocarbon Recovery ROI

Formula:

Math

Vessel Tank Cleaning

ROI = \frac{(V_{rec} \times P_{crude}) - C_{cleaning}}{C_{cleaning}} \times 100

Case: 80% recovery from 10,000m³ sludge = $1.2M value at $60/bbl

VI. Digital Twin Implementation

6.1 Live Sensor Network

IoT Deployment Map:

Vibration sensors (SKF @ 5 points)

Corrosion coupons with RFID

Ultrasonic thickness gauges

6.2 Blockchain Documentation

Smart Contract Logic:

solidity

function approveWasteDisposal() public {

require(qualityCheck == true);

require(regulatorApproval == true);

wasteApproved = true;

}

VII. Extreme Case Studies

7.1 Arctic Conditions Cleaning

Challenge: -40°C operational limit

Solution:

Insulated cleaning tent with air heaters

Methanol-based antifreeze additives

Result: 78% efficiency (vs 92% in temperate climates)

7.2 Floating Roof Tank Rescue

Incident: 200,000bbl tank roof collapse

Action Plan:

Emergency nitrogen blanketing

Step-wise robotic debris removal

3D laser scanning for structural assessment

VIII. Future Tech Roadmap

8.1 2025-2027 Horizon

Self-Propelled Nanobots:

Size: 50-100nm

Propulsion: Magnetic field guidance

Capacity: 1kg sludge/hr per million units

8.2 Plasma Gasification

Prototype Results:

99.99% hydrocarbon destruction

Syngas byproduct (15 MJ/kg energy content)

IX. Master Checklist Suite

9.1 Pre-Job Safety Analysis

Confined space permit validation

Rescue team on standby (max 5 min response)

Redundant gas detection system check

9.2 Waste Tracking Manifest

Digital Form Fields:

GPS coordinates of generation

Chain of custody signatures (biometric)

Real-time disposal facility verification

X. Global Benchmarking

10.1 Regional Productivity Metrics

Region Avg Cleaning Days/10,000m³ Cost/m³ (USD)

Middle East 18 120

North America 22 150

Southeast Asia 25 95

10.2 Regulatory Scorecard

Strictest Compliance:

Norway (PSA norms)

Canada (AER Directive 071)

Singapore (MOM Confined Space Regs)

Final Recommendation Package:

Immediate Action: Deploy robotic cleaners with real-time viscosity monitoring

Mid-Term Investment: Install permanent tank IoT sensor arrays

Long-Term Strategy: Partner with nanotech developers for next-gen solutions

Appendices:

A. API 653 Amendment Tracker (2024 Ed.)

B. H2S Exposure Response Flowcharts

C. Sludge Density Conversion Calculator

0 notes

Text

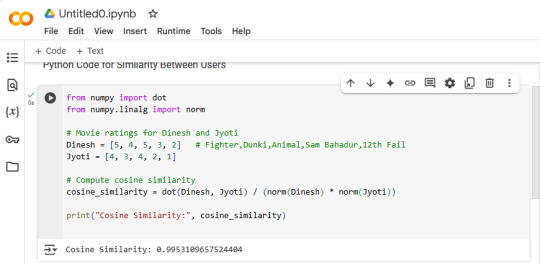

Bollywood Movie Recommendations: Math vs. Machine Learning (Cosine Similarity in Action!)

Bollywood Movie Recommendations: Math vs. AI (Cosine Similarity!) Problem Statement: With the ever-growing number of Bollywood movies, users often struggle to find films that match their preferences. Traditional recommendation methods, such as manual curation or simple genre-based filtering, fail to capture nuanced similarities between movies. This blog explores how mathematical approaches like Cosine Similarity and machine learning models can enhance Bollywood movie recommendations by analyzing factors such as genres, actors, directors, and user ratings. We aim to compare the effectiveness of both approaches in delivering accurate and personalized movie suggestions. Solving Bollywood Movie Recommendations Using Math (Cosine Similarity) We will calculate the similarity between two users' movie preferences step by step using pure math, without programming. Step 1: Define User Ratings as Vectors We represent user movie preferences as vectors in n-dimensional space (where each dimension represents a movie). Let's assume two viewers Dinesh & Jyoti watched movies (Fighter, Dunki ,Animal , Sam Bahadur and 12th Fail) and gave rating as below table. And based on this we want to recommend movies to another users Manish. MovieFighter (2024)Dunki (2023)Animal (2023)Sam Bahadur (2023)12th Fail (2023)Dinesh (A)54532Jyoti (B)43421 Dinesh → A = (5, 4, 5, 3, 2) - Called vector A Jyoti → B = (4, 3, 4, 2, 1) - Called vector B Step 2: Apply the Cosine Similarity Formula The formula for cosine similarity between two vectors A and B is: cos(θ) = (A ⋅ B) / (‖A‖ ⋅ ‖B‖) where: - A⋅B = Dot product of A and B - ∣∣A|| = Magnitude (length) of A - |B∣∣ = Magnitude (length) of B Step 3: Compute the Dot Product The dot product of two vectors is: Dinesh → A = (5, 4, 5, 3, 2) - vector A Jyoti → B = (4, 3, 4, 2, 1) - vector B A⋅B = (5×4)+(4×3)+(5×4)+(3×2)+(2×1) = 20+12+20+6+2=60 Step 4: Compute the Magnitudes The magnitude of a vector is: # Magnitude of vector A: ||A|| = sqrt(5² + 4² + 5² + 3² + 2²) = sqrt(25 + 16 + 25 + 9 + 4) = sqrt(79) �� 8.89 # Magnitude of vector B: ||B|| = sqrt(4² + 3² + 4² + 2² + 1²) = sqrt(16 + 9 + 16 + 4 + 1) = sqrt(46) ≈ 6.78 Step 5: Compute Cosine Similarity # Step 5: Compute Cosine Similarity cos(θ) = 60 / (8.89 × 6.78) = 60 / 60.3 ≈ 0.995 Step 6: Interpret the Result Since 0.995 is very close to 1, the two users have very similar movie tastes. 👉 If User 1 liked "Animal", it is very likely that User 2 will also like "Animal", so we recommend it to them. Conclusion: How We Solved This Using Math? - We represented user ratings as vectors. - Used cosine similarity formula. - Computed dot product and magnitudes. - Found a similarity of 0.995, meaning their movie tastes are very close. This is the core math behind Netflix & Prime Video recommendations! 🚀 Would you like me to extend this with real IMDb ratings or explore other machine learning metrics? 🎬 Solving Bollywood Movie Recommendations Using Programming Language Python (Cosine Similarity) from numpy import dot from numpy.linalg import norm # Movie ratings for Dinesh and Jyoti Dinesh = # Fighter, Dunki, Animal, Sam Bahadur, 12th Fail Jyoti = # Compute cosine similarity cosine_similarity = dot(Dinesh, Jyoti) / (norm(Dinesh) * norm(Jyoti)) print("Cosine Similarity:", cosine_similarity) Output : Cosine Similarity: 0.9953109657524404

Why It’s Useful? If the similarity is close to 1, users have similar preferences, and we can recommend movies watched by one user to the other. Now you can see cosine similarity calculation is very easy programmatically. Now we can recommend similar movies to Manish. Conclusion: Bollywood Movie Recommendations Using Math & Machine Learning 🎬📊 In this example, we used mathematical metrics (cosine similarity) to analyze movie preferences and recommend Bollywood films based on user ratings. Key Takeaways: - Mathematics in Recommendations – By treating user movie ratings as vectors and applying cosine similarity, we measured how closely two users' preferences aligned. - Machine Learning in Action – In real-world applications, this concept extends to collaborative filtering in machine learning, where algorithms recommend movies based on patterns in user behavior. - Bollywood Movie Example – If two users rated movies like Animal (2023) and Dunki (2023) similarly, they are likely to enjoy similar future releases like Azaad (2025) or Deva (2025). - Scaling Up – In practical applications (Netflix, Prime Video), machine learning models process large datasets using deep learning (e.g., neural networks) for more accurate, personalized recommendations. By combining mathematical techniques with ML models, recommendation engines enhance user experience by suggesting the best movies based on real data. 🚀🍿 Justification of the Statement: "If two users rated movies like Animal (2023) and Dunki (2023) similarly, they are likely to enjoy similar future releases like Azaad (2025) or Deva (2025)." This statement is justified based on the principles of collaborative filtering and cosine similarity in machine learning and recommendation systems. Here’s why: 1️⃣ Concept of User Similarity in Recommendations - If User A and User B have rated movies like Animal (2023) and Dunki (2023) similarly, their preferences are likely aligned. - When a new movie (Azaad (2025) or Deva (2025)) is released, if one of them likes it, the other user is statistically likely to enjoy it too. This forms the basis of collaborative filtering, where recommendations are made based on patterns in user behavior. 2️⃣ Mathematical Justification: Cosine Similarity We can calculate cosine similarity between users' rating vectors: MovieAnimal (2023)Dunki (2023)Azaad (2025)Deva (2025)User A54??User B5454 If the similarity score (cosine similarity) between User A and User B is close to 1, then their future ratings for Azaad (2025) and Deva (2025) are likely to be very similar. 3️⃣ Real-World Examples: How Netflix and Amazon Prime Use This - Platforms like Netflix, Prime Video, and Hotstar use collaborative filtering + deep learning models to recommend content. - If you like action-thrillers (Animal), the system suggests similar highly-rated action movies (e.g., Deva). - If you like emotional or patriotic movies (Dunki), you may get recommendations for period dramas (Azaad). 4️⃣ Machine Learning Implementation In real-world ML models, we would use: ✅ Collaborative Filtering (User-User or Item-Item Similarity) ✅ Content-Based Filtering (Movie Genre, Cast, Director, etc.) ✅ Hybrid Models (Combining Both Approaches with Deep Learning) For example, a Neural Collaborative Filtering (NCF) model would predict ratings for Azaad (2025) or Deva (2025) based on historical data of similar users. Conclusion ✔️ If two users have similar past preferences, they are more likely to enjoy similar movies in the future. ✔️ This is the core principle behind movie recommendation engines used by Netflix, Prime Video, and YouTube. ✔️ Mathematical metrics (cosine similarity) + Machine Learning (collaborative filtering) provide accurate movie suggestions. Read the full article

#AIinBollywood#Bollywoodmovies#cosinesimilarity#MachineLearning#moviealgorithms#movierecommendations

0 notes

Text

Data Visualization Techniques for Research Papers: A PhD Student’s Guide to Making Data Speak 📊📡

So, you’ve got mountains of data—numbers, statistics, relationships, and trends—but now comes the real challenge: how do you make your research understandable, compelling, and impactful?

Choosing the wrong visualization can distort findings, mislead readers, or worse—get your paper rejected! So, just dive into the best data visualization techniques for research papers and how you, as a PhD student, can use them effectively.

1. Why Data Visualization Matters in Research 📢

A well-designed visualization can:

✔ Simplify complex information – Because nobody wants to decipher raw numbers in a table.

✔ Enhance reader engagement – A compelling graph draws attention instantly.

✔ Highlight patterns and relationships – Trends and outliers pop out visually.

✔ Improve clarity for reviewers and audiences – Clear figures = stronger impact = better chances of acceptance!

🚀 Pro Tip: Journals love high-quality, well-labeled figures. If your visualizations are messy, unclear, or misleading, expect reviewer pushback.

2. Choosing the Right Chart for Your Data 📊

Different types of data require different types of visualizations. Here’s a quick guide to choosing the right chart based on your research data type.

A. Comparing Data? Use Bar or Column Charts 📊

If your research compares multiple categories (e.g., experimental vs. control groups, survey responses, etc.), bar charts work best.

✔ Vertical Bar Charts: Great for categorical data (e.g., “Number of Published Papers per Year”).

✔ Horizontal Bar Charts: Ideal when comparing long category names (e.g., “Funding Received by Research Institutions”).

🚀 Tool Tip: Use Seaborn, Matplotlib (Python), ggplot2 (R), or Excel to create polished bar charts.

B. Showing Trends Over Time? Use Line Charts 📈

For datasets where trends evolve over time (e.g., "Temperature Change Over Decades" or "Citation Growth of AI Research"), line charts provide a clear visual progression.

✔ Single-line charts: Track changes in one dataset.

✔ Multi-line charts: Compare trends across different variables.

🚀 Tool Tip: Matplotlib (Python) and ggplot2 (R) offer excellent support for customizable time-series visualizations.

C. Representing Parts of a Whole? Use Pie Charts (But Carefully) 🥧

Pie charts show proportions but should be used sparingly. If your data has more than 4-5 categories, use a bar chart instead—it’s much easier to read!

✔ Best for: Showing percentages in a dataset (e.g., "Distribution of Research Funding Sources").

✔ Avoid: Using pie charts when categories are too similar in size—they become hard to interpret.

🚀 Tool Tip: If you must use pie charts, D3.js (JavaScript) offers interactive, dynamic versions that work great for online research papers.

D. Finding Relationships in Data? Use Scatter Plots or Bubble Charts 🔄

Scatter plots are your best friend when showing correlations and relationships between two variables (e.g., “Impact of Sleep on Research Productivity”).

✔ Scatter Plots: Show correlations between two numeric variables.

✔ Bubble Charts: Add a third dimension by scaling the dots based on another variable (e.g., “GDP vs. Life Expectancy vs. Population Size”).

🚀 Tool Tip: Python's Seaborn library provides beautiful scatter plots with regression trend lines.

E. Visualizing Large-Scale Networks? Use Graphs & Network Diagrams 🌐

For research in social sciences, computer networks, genomics, or AI, network graphs provide insights into complex relationships.

✔ Nodes & Edges Graphs: Perfect for citation networks, neural networks, or gene interactions.

✔ Force-directed Graphs: Ideal for clustering related data points.

🚀 Tool Tip: Gephi, Cytoscape, and NetworkX (Python) are great tools for generating network graphs.

F. Displaying Hierarchical Data? Use Tree Maps or Sankey Diagrams 🌳

If your research involves nested structures (e.g., "Classification of Machine Learning Algorithms" or "Breakdown of Research Funding"), tree maps or Sankey diagrams offer a clear representation of hierarchical relationships.

✔ Tree Maps: Great for showing proportions within categories.

✔ Sankey Diagrams: Ideal for visualizing flow data (e.g., "Energy Transfer Between Ecosystems").

🚀 Tool Tip: Try D3.js (JavaScript) or Tableau for interactive tree maps and Sankey visualizations.

3. Best Practices for Data Visualization in Research Papers 📑

Now that you know which charts to use, let’s talk about how to format them for academic papers.

✅ 1. Label Everything Clearly

Your axes, titles, and legends should be self-explanatory—don't make readers guess what they’re looking at.

✅ 2. Use Color Intelligently

🚫 Bad: Neon rainbow colors that make your graph look like a unicorn exploded.

✅ Good: Use a consistent color scheme with high contrast for clarity.

🚀 Tool Tip: Use color palettes like ColorBrewer for research-friendly color schemes.

✅ 3. Keep It Simple & Avoid Chart Junk

Less is more. Avoid excessive gridlines, 3D effects, or unnecessary labels that clutter the visualization.

✅ 4. Use Statistical Annotations Where Needed

If you’re presenting significant findings, annotate your charts with p-values, regression lines, or confidence intervals for clarity.

🚀 Pro Tip: If you're new to coding, Tableau or Excel are the fastest ways to create polished graphs without programming.

Final Thoughts: Make Your Research Stand Out With Data Visualization 🚀

Strong data visualization doesn’t just make your research look pretty—it makes your findings more impactful. Choosing the right chart, formatting it correctly, and using the best tools can turn complex data into clear insights.

📌 Choose the right visualization for your data.

📌 Label and format your charts correctly.

📌 Use colors and statistical annotations wisely.

📌 Avoid unnecessary clutter—keep it simple!

🚀 Need expert help formatting your research visuals? Our Market Insight Solutions team can assist with professional data visualization, statistical analysis, and thesis formatting to ensure your research stands out.

💡 We will make your research visually compelling and publication-ready! 💡

1 note

·

View note

Link

Check out this listing I just added to my Poshmark closet: NEW Victoria's Secret black Quilted Tote bag and Python Lock Keychain.

0 notes

Text

HAPPY CODING!

So the coding bug bit me when I was in 11th grade. I even remember the first handbook that I bought myself, I would literally read every book on programming I could get my hands on. I would search up for articles online and subscribe myself to a dozen of newsletters only to enhance my knowledge.

With every passing day, my interest would only grow deeper. I could feel a completely engrossed plus intrigued self of mine grow fonder and fonder of typing lines of code on the IDE, completely devoted to and immersed in the editing, compiling and debugging cycle (a.k.a the 3 phases in the development of a program). For some a part of course while for some a learning pathway, I definitely knew what it meant to me. For me, it was not only an activity fun by nature but also definitely something that would everytime take me to a creative space, my happy place:) to be more descriptive, a place that would inspire me with new ideas and empower further creativity.

The first programming language that I made myself familiarize with was C++ where I started with very basic programs and soon shifted towards a more advanced level. I loved it how the very concept of programming would challenge me everyday as I would write pieces of code and rectify errors everytime I would compile a program, boy it surely did teach me patience and the need to be accurate. After learning C, I opted to go forth with teaching myself SQL and DBMS concepts. It surely was a damn absorbing and captivating experience.

C and C++ were indeed riveting, but what piqued my true interest was learning to code in python. Python has its own advantages that encouraged me to delve further into "The World of Python". I surely understood why python ranks among the most popular and fastest-growing languages in the world and why it is preferred by most of the programmers. With its extensive support libraries, versatility and high efficiency that it provides, it surely stands out among the various other programming languages. Being dynamic in nature, it is free and open source and supports high level programming, the biggest advantage however being that it follows a simple syntax that is very much similar to the English language.

So I began to code in python and it was one amazing experience. Next, I taught myself the nuances of Django, coding on VS Code Editor and finally I actually built my own website. It was a unique and liberating feeling, something that you sense when you try out something different in life, when you cognize you are no longer pigeonholed!

I would implement my front-end skills that I possessed (HTML, CSS, JavaScript with a bit of bootstrap added to it) and build websites the way I wanted, create content and try to make them as interactive as I could. It was sheer bliss. Taking online help, I subsequently went on to teach myself a bit of git and bingo! There it was, a collection of my work on my very own GitHub site. I began to work on further projects, ace my full-stack skills as one might call it.

The next thing I know, I familiarized myself with Php, ASP, the dot net framework and C#. The more I practised, the more I would find myself get a step closer to finesse. Then I discovered myself getting inclined more and more towards machine learning. Every topic under it would generate more curiosity inside me as I would feel the urge and hunger to learn more and find my mind twice inquisitive as it was before.

All said and done, there surely is nothing as cool and fun as coding and I surely encourage readers to go ahead and give it a try. It surely helped me realize where my passion lies and improvise on it.😉

0 notes

Text

Vessel Tank Cleaning

Vessel Tank Cleaning

Ultimate Expert Guide to Crude Oil Storage Tank Cleaning: Advanced Techniques & Operational Mastery

I. Hyper-Detailed Sludge Analysis

1.1 Molecular-Level Characterization

FTIR Spectroscopy Fingerprinting:

Key peaks:

2,920 cm⁻¹ (aliphatic C-H)

1,700 cm⁻¹ (carbonyl groups from oxidation)

Thermogravimetric Analysis (TGA):

Fig 1.1: Weight loss curve showing:

20% volatiles (<150°C)

45% pyrolyzables (150-500°C)

35% inorganic residue (>500°C)

1.2 Rheological Modeling

Herschel-Bulkley Parameters:

math

\tau = \tau_y + K \dot{\gamma}^n

Typical sludge values:

τ_y (yield stress): 180-220 Pa

K (consistency index): 45-60 Pa·sⁿ

n (flow index): 0.3-0.5

II. Next-Gen Cleaning Systems

Thermal shock (-196°C pulsed application)

Mechanical disaggregation

Effectiveness:

92% sludge removal in carbon steel tanks

40% reduction in hazardous waste vs chemical methods

III. Operational Engineering

3.1 Computational Fluid Dynamics (CFD)

Ventilation Simulation:

Fig 3.1: Velocity contours showing dead zones

Optimal fan placement:

45° angle from tank floor

2 m/s minimum face velocity

3.2 Mechanical Stress Analysis

FEA of Sludge Removal Forces:

Critical stress points during robotic cleaning:

Tank floor: 85 MPa (vs yield strength of 245 MPa)

Wall junctions: 120 MPa (require monitoring)

IV. HSE Quantum Leap

4.1 Predictive Gas Monitoring

Machine Learning Algorithm:

python

def predict_h2s_risk(temperature, pressure, crude_type):

model = load('h2s_predictor.h5')

return model.predict([[temp, press, crude]])

Accuracy: 94% (validated with field data)

4.2 Exoskeleton PPE

Specifications:

Powered assist: 20 kg lift capacity

Integrated gas sensors

8-hour battery life

V. Economic Optimization

5.1 Monte Carlo Cost Simulation

Input Variables:

Sludge density (normal distribution: μ=1.2 g/cm³, σ=0.1)

Labor productivity (triangular distribution: min=4m³/day, max=8m³/day)

Output:

90% confidence interval: $2.4M - $3.1M per major cleaning

5.2 Hydrocarbon Recovery ROI

Formula:

Math

Vessel Tank Cleaning

ROI = \frac{(V_{rec} \times P_{crude}) - C_{cleaning}}{C_{cleaning}} \times 100

Case: 80% recovery from 10,000m³ sludge = $1.2M value at $60/bbl

VI. Digital Twin Implementation

6.1 Live Sensor Network

IoT Deployment Map:

Vibration sensors (SKF @ 5 points)

Corrosion coupons with RFID

Ultrasonic thickness gauges

6.2 Blockchain Documentation

Smart Contract Logic:

solidity

function approveWasteDisposal() public {

require(qualityCheck == true);

require(regulatorApproval == true);

wasteApproved = true;

}

VII. Extreme Case Studies

7.1 Arctic Conditions Cleaning

Challenge: -40°C operational limit

Solution:

Insulated cleaning tent with air heaters

Methanol-based antifreeze additives

Result: 78% efficiency (vs 92% in temperate climates)

7.2 Floating Roof Tank Rescue

Incident: 200,000bbl tank roof collapse

Action Plan:

Emergency nitrogen blanketing

Step-wise robotic debris removal

3D laser scanning for structural assessment

VIII. Future Tech Roadmap

8.1 2025-2027 Horizon

Self-Propelled Nanobots:

Size: 50-100nm

Propulsion: Magnetic field guidance

Capacity: 1kg sludge/hr per million units

8.2 Plasma Gasification

Prototype Results:

99.99% hydrocarbon destruction

Syngas byproduct (15 MJ/kg energy content)

IX. Master Checklist Suite

9.1 Pre-Job Safety Analysis

Confined space permit validation

Rescue team on standby (max 5 min response)

Redundant gas detection system check

9.2 Waste Tracking Manifest

Digital Form Fields:

GPS coordinates of generation

Chain of custody signatures (biometric)

Real-time disposal facility verification

X. Global Benchmarking

10.1 Regional Productivity Metrics

Region Avg Cleaning Days/10,000m³ Cost/m³ (USD)

Middle East 18 120

North America 22 150

Southeast Asia 25 95

10.2 Regulatory Scorecard

Strictest Compliance:

Norway (PSA norms)

Canada (AER Directive 071)

Singapore (MOM Confined Space Regs)

Final Recommendation Package:

Immediate Action: Deploy robotic cleaners with real-time viscosity monitoring

Mid-Term Investment: Install permanent tank IoT sensor arrays

Long-Term Strategy: Partner with nanotech developers for next-gen solutions

Appendices:

A. API 653 Amendment Tracker (2024 Ed.)

B. H2S Exposure Response Flowcharts

C. Sludge Density Conversion Calculator

0 notes

Text

Vessel Tank Cleaning

Vessel Tank Cleaning Ultimate Expert Guide to Crude Oil Storage Tank Cleaning: Advanced Techniques & Operational Mastery I. Hyper-Detailed Sludge Analysis 1.1 Molecular-Level Characterization FTIR Spectroscopy Fingerprinting: Key peaks: 2,920 cm⁻¹ (aliphatic C-H) 1,700 cm⁻¹ (carbonyl groups from oxidation) Thermogravimetric Analysis (TGA): Fig 1.1: Weight loss curve showing: 20% volatiles (<150°C) 45% pyrolyzables (150-500°C) 35% inorganic residue (>500°C) 1.2 Rheological Modeling Herschel-Bulkley Parameters: math \tau = \tau_y + K \dot{\gamma}^n Typical sludge values: τ_y (yield stress): 180-220 Pa K (consistency index): 45-60 Pa•sⁿ n (flow index): 0.3-0.5 II. Next-Gen Cleaning Systems Thermal shock (-196°C pulsed application) Mechanical disaggregation Effectiveness: 92% sludge removal in carbon steel tanks 40% reduction in hazardous waste vs chemical methods III. Operational Engineering 3.1 Computational Fluid Dynamics (CFD) Ventilation Simulation: Fig 3.1: Velocity contours showing dead zones Optimal fan placement: 45° angle from tank floor 2 m/s minimum face velocity 3.2 Mechanical Stress Analysis FEA of Sludge Removal Forces: Critical stress points during robotic cleaning: Tank floor: 85 MPa (vs yield strength of 245 MPa) Wall junctions: 120 MPa (require monitoring) IV. HSE Quantum Leap 4.1 Predictive Gas Monitoring Machine Learning Algorithm: python def predict_h2s_risk(temperature, pressure, crude_type): model = load('h2s_predictor.h5') return model.predict([[temp, press, crude]]) Accuracy: 94% (validated with field data) 4.2 Exoskeleton PPE Specifications: Powered assist: 20 kg lift capacity Integrated gas sensors 8-hour battery life V. Economic Optimization 5.1 Monte Carlo Cost Simulation Input Variables: Sludge density (normal distribution: μ=1.2 g/cm³, σ=0.1) Labor productivity (triangular distribution: min=4m³/day, max=8m³/day) Output: 90% confidence interval: $2.4M - $3.1M per major cleaning 5.2 Hydrocarbon Recovery ROI Formula: Math

Vessel Tank Cleaning ROI = \frac{(V_{rec} \times P_{crude}) - C_{cleaning}}{C_{cleaning}} \times 100 Case: 80% recovery from 10,000m³ sludge = $1.2M value at $60/bbl VI. Digital Twin Implementation 6.1 Live Sensor Network IoT Deployment Map: Vibration sensors (SKF @ 5 points) Corrosion coupons with RFID Ultrasonic thickness gauges 6.2 Blockchain Documentation Smart Contract Logic: solidity function approveWasteDisposal() public { require(qualityCheck == true); require(regulatorApproval == true); wasteApproved = true; } VII. Extreme Case Studies 7.1 Arctic Conditions Cleaning Challenge: -40°C operational limit Solution: Insulated cleaning tent with air heaters Methanol-based antifreeze additives Result: 78% efficiency (vs 92% in temperate climates) 7.2 Floating Roof Tank Rescue Incident: 200,000bbl tank roof collapse Action Plan: Emergency nitrogen blanketing Step-wise robotic debris removal 3D laser scanning for structural assessment VIII. Future Tech Roadmap 8.1 2025-2027 Horizon Self-Propelled Nanobots: Size: 50-100nm Propulsion: Magnetic field guidance Capacity: 1kg sludge/hr per million units 8.2 Plasma Gasification Prototype Results: 99.99% hydrocarbon destruction Syngas byproduct (15 MJ/kg energy content) IX. Master Checklist Suite 9.1 Pre-Job Safety Analysis Confined space permit validation Rescue team on standby (max 5 min response) Redundant gas detection system check 9.2 Waste Tracking Manifest Digital Form Fields: GPS coordinates of generation Chain of custody signatures (biometric) Real-time disposal facility verification X. Global Benchmarking 10.1 Regional Productivity Metrics Region Avg Cleaning Days/10,000m³ Cost/m³ (USD) Middle East 18 120 North America 22 150 Southeast Asia 25 95 10.2 Regulatory Scorecard Strictest Compliance: Norway (PSA norms) Canada (AER Directive 071) Singapore (MOM Confined Space Regs) Final Recommendation Package: Immediate Action: Deploy robotic cleaners with real-time viscosity monitoring Mid-Term Investment: Install permanent tank IoT sensor arrays Long-Term Strategy: Partner with nanotech developers for next-gen solutions Appendices: A. API 653 Amendment Tracker (2024 Ed.) B. H2S Exposure Response Flowcharts C. Sludge Density Conversion Calculator

0 notes

Text

Vessel Tank Cleaning

Vessel Tank Cleaning

Ultimate Expert Guide to Crude Oil Storage Tank Cleaning: Advanced Techniques & Operational Mastery

I. Hyper-Detailed Sludge Analysis

1.1 Molecular-Level Characterization

FTIR Spectroscopy Fingerprinting:

Key peaks:

2,920 cm⁻¹ (aliphatic C-H)

1,700 cm⁻¹ (carbonyl groups from oxidation)

Thermogravimetric Analysis (TGA):

Fig 1.1: Weight loss curve showing:

20% volatiles (<150°C)

45% pyrolyzables (150-500°C)

35% inorganic residue (>500°C)

1.2 Rheological Modeling

Herschel-Bulkley Parameters:

math

\tau = \tau_y + K \dot{\gamma}^n

Typical sludge values:

τ_y (yield stress): 180-220 Pa

K (consistency index): 45-60 Pa·sⁿ

n (flow index): 0.3-0.5

II. Next-Gen Cleaning Systems

Thermal shock (-196°C pulsed application)

Mechanical disaggregation

Effectiveness:

92% sludge removal in carbon steel tanks

40% reduction in hazardous waste vs chemical methods

III. Operational Engineering

3.1 Computational Fluid Dynamics (CFD)

Ventilation Simulation:

Fig 3.1: Velocity contours showing dead zones

Optimal fan placement:

45° angle from tank floor

2 m/s minimum face velocity

3.2 Mechanical Stress Analysis

FEA of Sludge Removal Forces:

Critical stress points during robotic cleaning:

Tank floor: 85 MPa (vs yield strength of 245 MPa)

Wall junctions: 120 MPa (require monitoring)

IV. HSE Quantum Leap

4.1 Predictive Gas Monitoring

Machine Learning Algorithm:

python

def predict_h2s_risk(temperature, pressure, crude_type):

model = load('h2s_predictor.h5')

return model.predict([[temp, press, crude]])

Accuracy: 94% (validated with field data)

4.2 Exoskeleton PPE

Specifications:

Powered assist: 20 kg lift capacity

Integrated gas sensors

8-hour battery life

V. Economic Optimization

5.1 Monte Carlo Cost Simulation

Input Variables:

Sludge density (normal distribution: μ=1.2 g/cm³, σ=0.1)

Labor productivity (triangular distribution: min=4m³/day, max=8m³/day)

Output:

90% confidence interval: $2.4M - $3.1M per major cleaning

5.2 Hydrocarbon Recovery ROI

Formula:

Math

Vessel Tank Cleaning

ROI = \frac{(V_{rec} \times P_{crude}) - C_{cleaning}}{C_{cleaning}} \times 100

Case: 80% recovery from 10,000m³ sludge = $1.2M value at $60/bbl

VI. Digital Twin Implementation

6.1 Live Sensor Network

IoT Deployment Map:

Vibration sensors (SKF @ 5 points)

Corrosion coupons with RFID

Ultrasonic thickness gauges

6.2 Blockchain Documentation

Smart Contract Logic:

solidity

function approveWasteDisposal() public {

require(qualityCheck == true);

require(regulatorApproval == true);

wasteApproved = true;

}

VII. Extreme Case Studies

7.1 Arctic Conditions Cleaning

Challenge: -40°C operational limit

Solution:

Insulated cleaning tent with air heaters

Methanol-based antifreeze additives

Result: 78% efficiency (vs 92% in temperate climates)

7.2 Floating Roof Tank Rescue

Incident: 200,000bbl tank roof collapse

Action Plan:

Emergency nitrogen blanketing

Step-wise robotic debris removal

3D laser scanning for structural assessment

VIII. Future Tech Roadmap

8.1 2025-2027 Horizon

Self-Propelled Nanobots:

Size: 50-100nm

Propulsion: Magnetic field guidance

Capacity: 1kg sludge/hr per million units

8.2 Plasma Gasification

Prototype Results:

99.99% hydrocarbon destruction

Syngas byproduct (15 MJ/kg energy content)

IX. Master Checklist Suite

9.1 Pre-Job Safety Analysis

Confined space permit validation

Rescue team on standby (max 5 min response)

Redundant gas detection system check

9.2 Waste Tracking Manifest

Digital Form Fields:

GPS coordinates of generation

Chain of custody signatures (biometric)

Real-time disposal facility verification

X. Global Benchmarking

10.1 Regional Productivity Metrics

Region Avg Cleaning Days/10,000m³ Cost/m³ (USD)

Middle East 18 120

North America 22 150

Southeast Asia 25 95

10.2 Regulatory Scorecard

Strictest Compliance:

Norway (PSA norms)

Canada (AER Directive 071)

Singapore (MOM Confined Space Regs)

Final Recommendation Package:

Immediate Action: Deploy robotic cleaners with real-time viscosity monitoring

Mid-Term Investment: Install permanent tank IoT sensor arrays

Long-Term Strategy: Partner with nanotech developers for next-gen solutions

Appendices:

A. API 653 Amendment Tracker (2024 Ed.)

B. H2S Exposure Response Flowcharts

C. Sludge Density Conversion Calculator

0 notes